Installation Instructions For Vincent "32mm Big Bore" Intake Manifolds.

1) Prepare the bike for manifold installation by removing the seat, and fuel tank.

2) Remove the original fuel line, throttle cables, choke cables, original carbs, and the original manifolds. Original manifold mounting nuts will be re-used!

3) Install the new manifolds, and take a sharp pointed scribe to do a tracing onto the head at the intake ports. This is a visible guide for cleaning out some head material to "port-match" the new manifolds to the heads.

4) Stuff some paper towels into the ports very tightly, so no grinding material will enter the cylinders (first check that both intake valves are slightly opened for blowing air through in the reverse direction later). Use a Dremmel tool with a sanding drum attached to carefully remove port material to match the line that was scribed.

5) Vacuum clean any grinding debris from the intake ports before removing the paper towels.

6) Remove the spark plugs, and blow air into the spark plug holes to flush out any grinding debris while carefully removing the paper towels. Carefully remove any grinding debris!

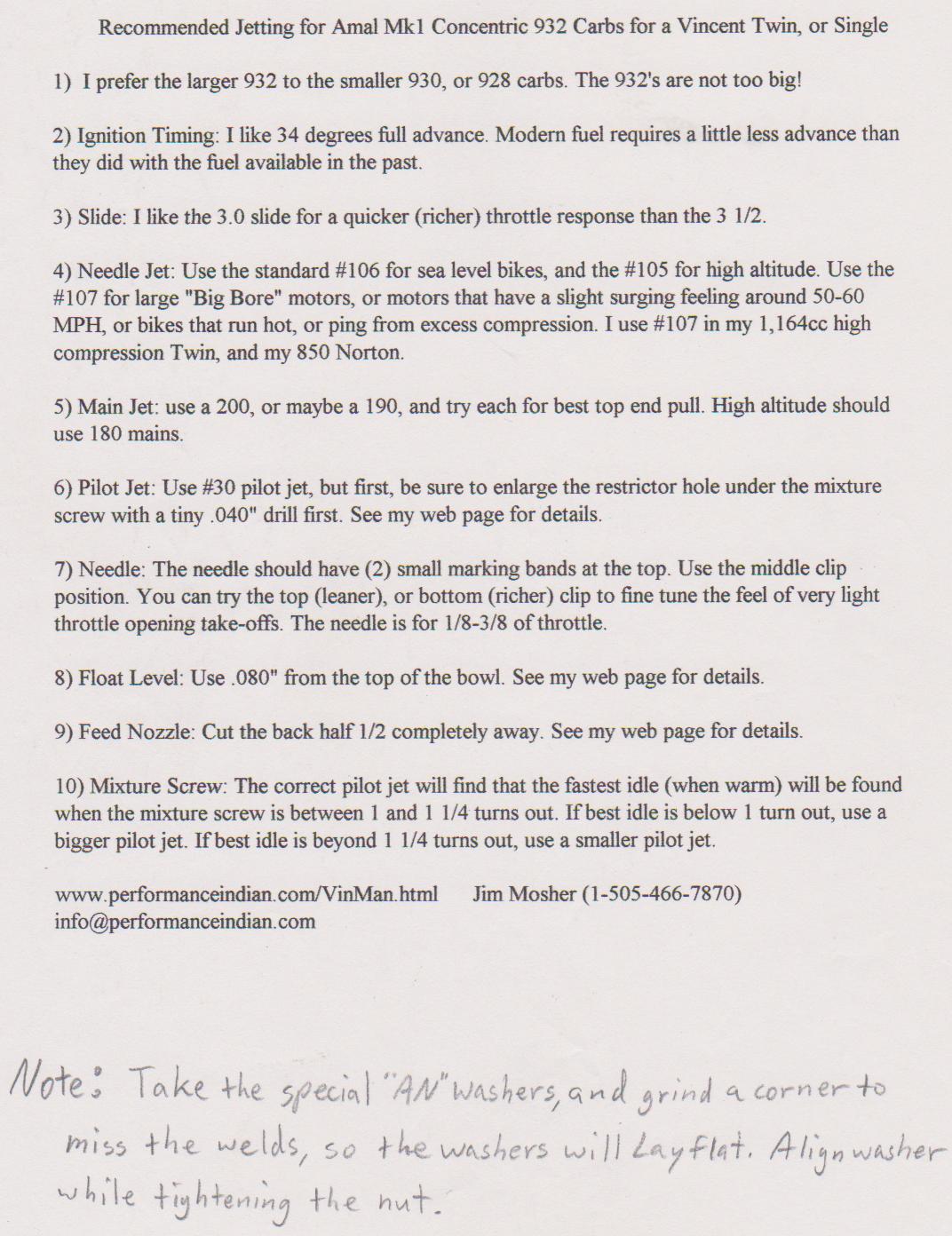

7) Re-install the new manifolds, and install the new 932 Concentric carbs (make sure all jetting changes, and carb mods are already done!). It is hard to do jetting changes later!

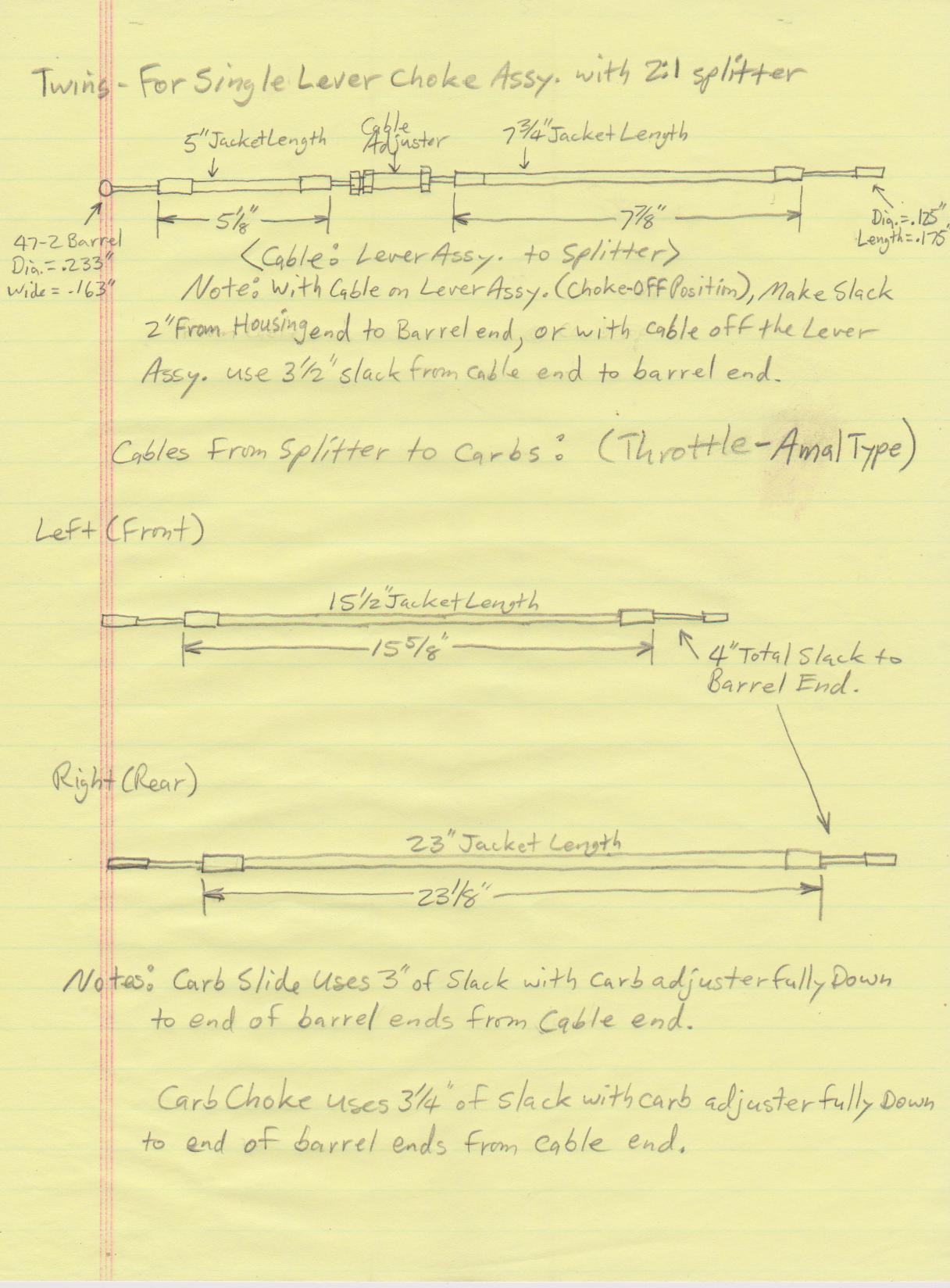

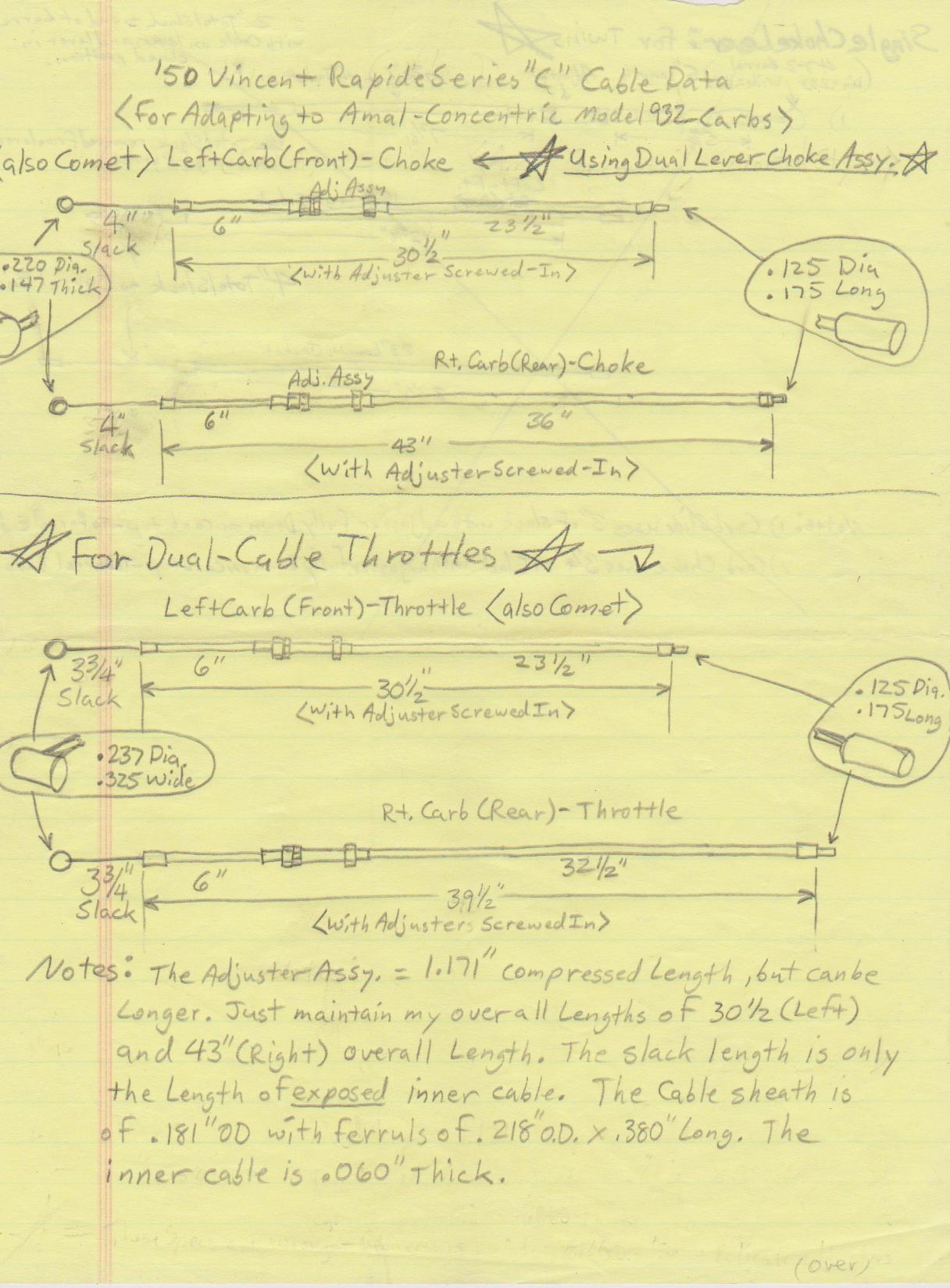

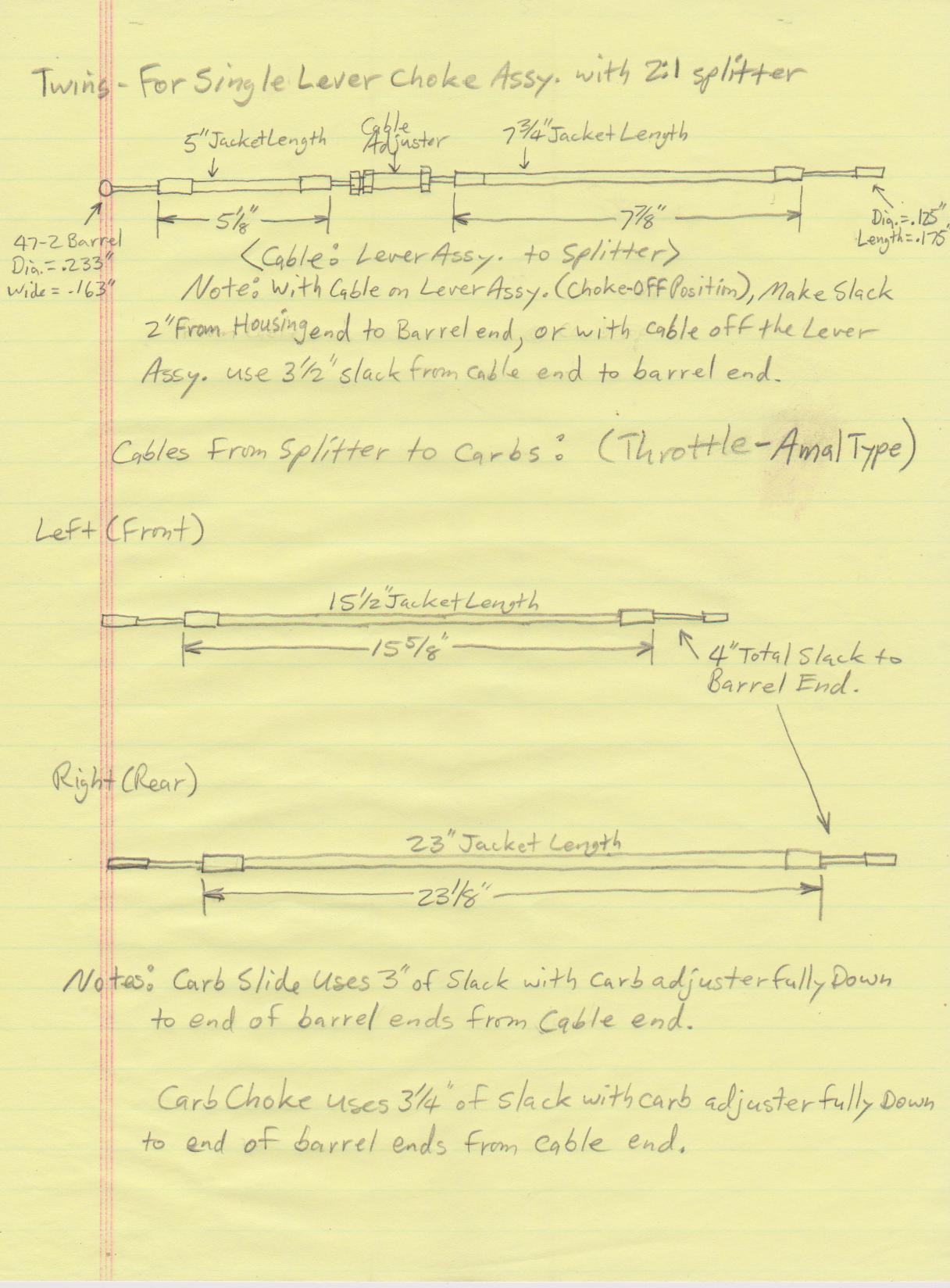

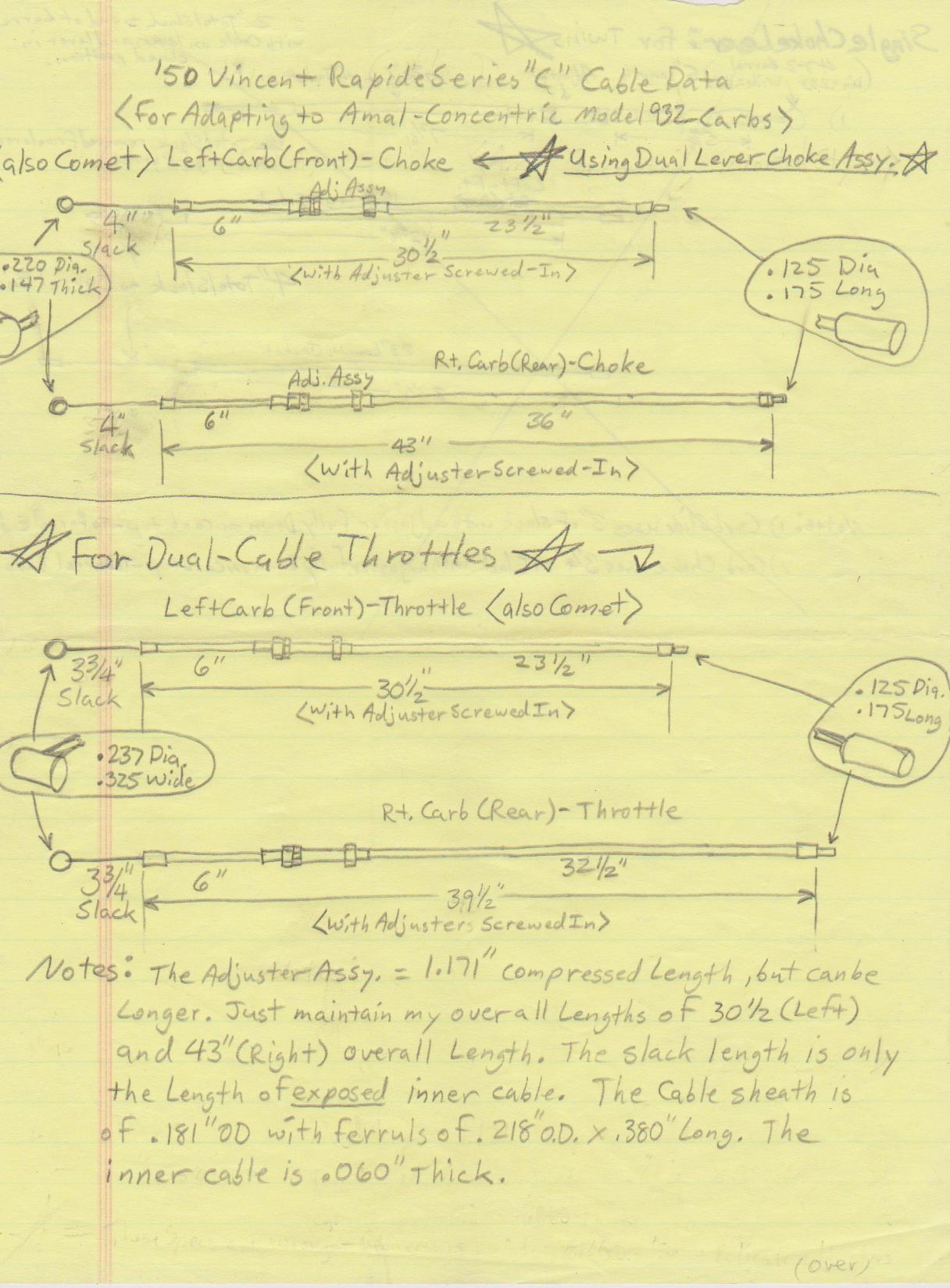

8) Make new throttle, and choke cables. I preffer to use (2) throttle cables(one per carb) using a "dual-pull" throttle, instead of a "single pull" throttle with a 2:1 splitter adapter. I use a single pull choke lever, and the 2:1 splitter adapter on the choke cables. This is because of better cable routing, better choke control, and less stress on a single pull throttle cable.

9) Carefully route the cables for the best flow (no kinks, or sharp bends). Run the right throttle cable along the right side of the oil tank, and the left throttle cable along the left side of the oil tank. Run the choke cable down through the upper fork yoke along the left side of the shock absorber, then crossing over the fork neck, and terminating into the 2:1 splitter adapter just under the fuel tanks front/right mounting bracket. Run the right choke cable along the right side of the oil tank, and the left choke cable under the oil tank to the left carb. I like to tape these cables to the oil tank out of view to hold them securely while re-installing the fuel tank. Unfortunately the Vincent fuel tank is a very tight fit to the oil tank, and some re-adjusting of the cables may be required for a good final fit.

10) Carefully adjust the initial slack into each cable before installing the fuel tank. Part of the carb setup (mentioned in the tuning tips section) is the initial setup of the carbs slide height, and adjustable ends where the throttle, and choke cables meet the carb top. Do these adjustments first on the bench! Adjust cable slack with the "in-line" cable adjusters so there is a very slight slack at the carb tops that closely match each other. Use the same amount of slack at all (4) cables at the carb tops.

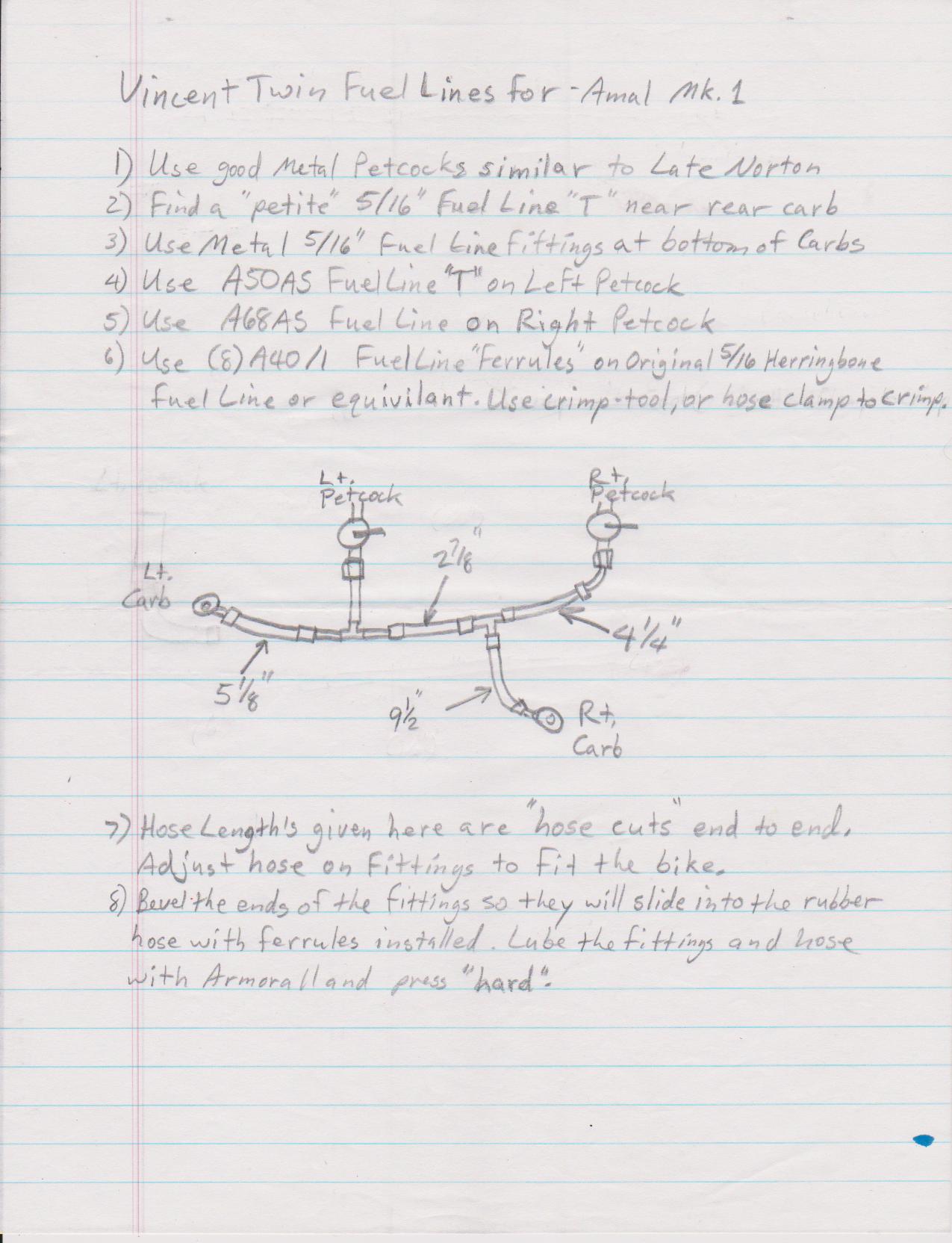

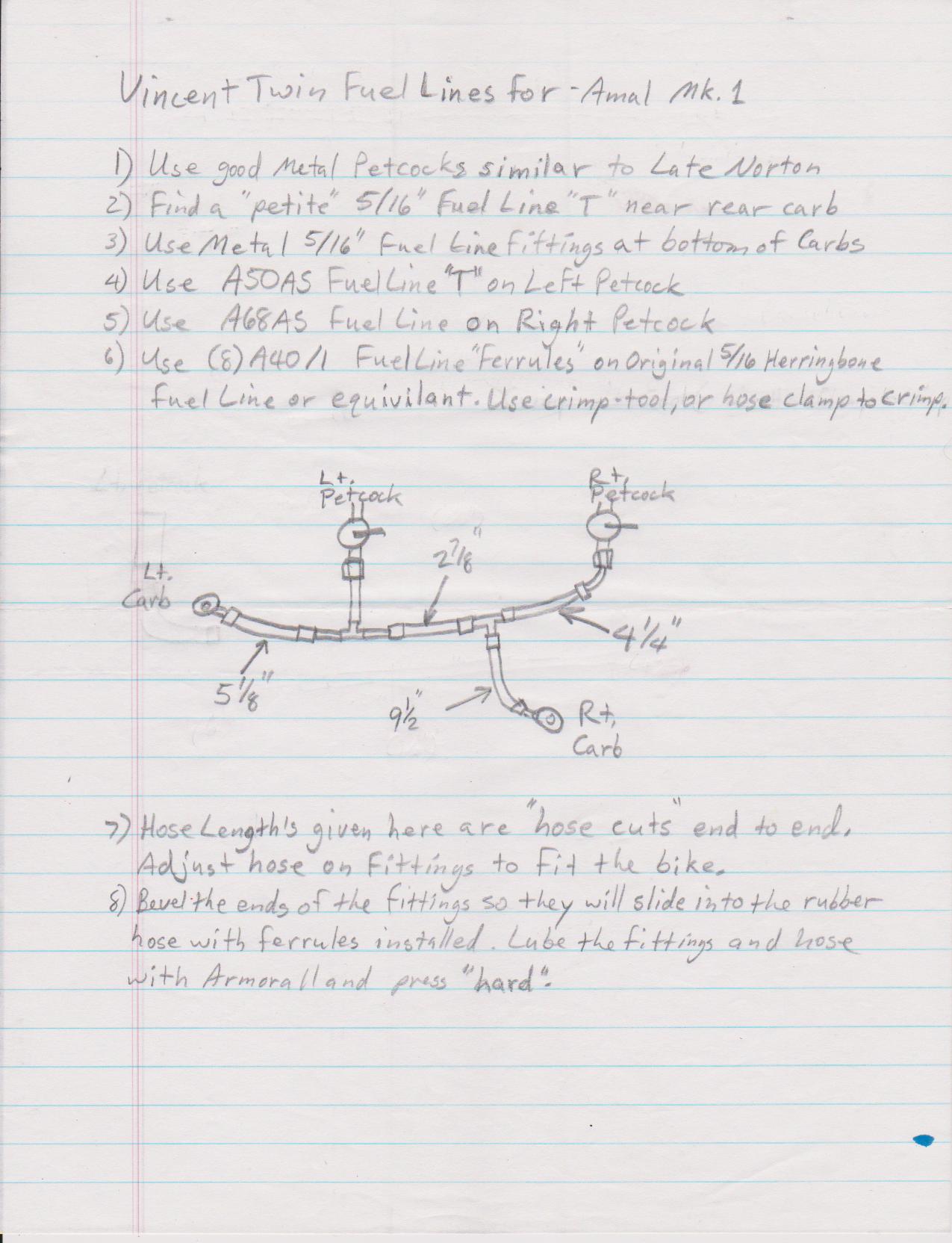

11) After re-installing the fuel tank, install the original fuel line, and observe where the ends will need to be modified to match-up to the new 932's fuel inlets. New carbs come with plastic fuel inlets, and a careful search can come up with earlier "pot-metal" inlets. The plastic units will work fine, but metal is best!

12) Check the cable slack by first observing how the choke slides lift when the choke lever is just slightly opened. They should both lift at exactly the same amount at all times. Use the carb top adjusters to achieve this careful adjustment. The chokes are now finished. Then observe the throttle slides rate of opening, and they should just lift off the idle stop screws at the exact moment. Adjust this at the carbs top adjustments. This will roughly balance the opening function of the throttle cables.

13) Start the bike, and let it warm up. It may run rough, so don't let it die while finishing the fine adjustments. First the idle speed needs to be set. Since the carbs idle stop screws, and throttle cables were "roughed-in", both carbs idle stop screws should be rough adjusted up or down in equal amounts. Don't go wild with these screw adjustments. It is best to fine tune with a "Uni-Syn" adjusting tool by Eledbrock, that can still be bought at Summit Racing (www.summitracing.com 1-800-230-3030) for $24.95. Ask for an "Edelbrock Uni-Syn" (part# EDL-4025). A twin carb bike CAN NOT be properly balanced without this tool. It is used to check each carb against the other to see the amount of air flow while the motor is running. It is first used to balance the idle stop screws for a nice idle speed with equal air flow at idle. Then it is used to check the balance of the throttle cable against each other while the throttle is just slightly opened to get the slides off their idle stop screws. Last, carefully adjust the idle mixture screws (in, or out while keeping them equal to each other) for the fastest idle speed. Now using the Uni-Syn, re-adjust the final idle speed. It is a good idea to use a fan to blow alot of air across the motor to help keep it cool.

14) Check your ignition timing, and points setting to finalize your tune-up. Now go ride!

CONTACT INFORMATION:

James R. Mosher

(505) 466-7870