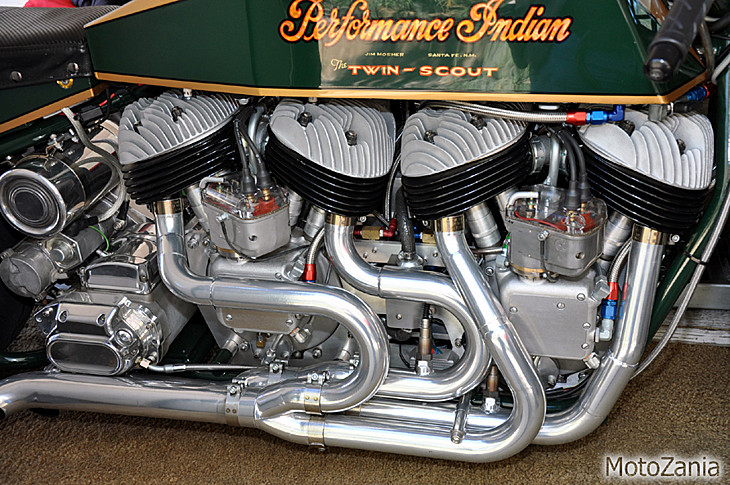

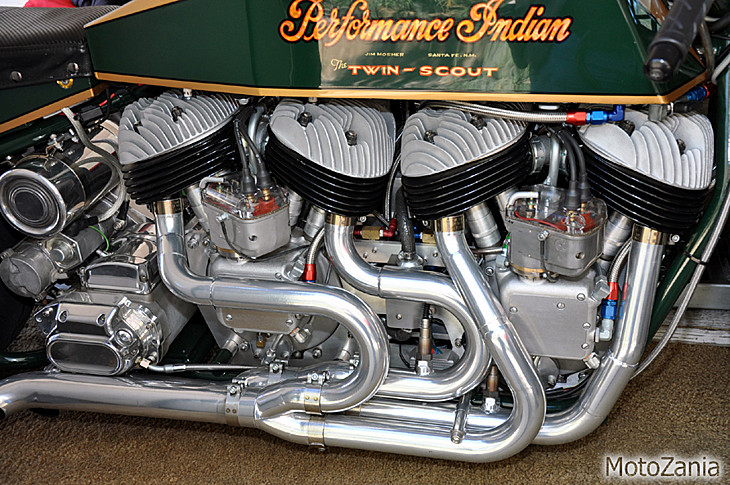

Race #2 (58" Stroker Scout Motor) Info

Of these (3) motors in the pic above, the one in the middle is "Race #1", one of the "Series One" race motors from My Twin-Scout Land Speed Racer (the front motor). The motor on the left is Race #2, or the rear motor. These (2) motors are identical clones, with just slightly different measured internal dimensions. I did a seperate page for each motor, so you can see the individual spec sheets for each motor. Otherwise, the individual parts costs, and total costs are the same for each motor. I have over $20,000.00 invested in each motor, with a lot of custom made parts, and outside services. So, yes, I am taking a loss here. But, they got the job done for me in shining glory! They have set (10) new Land Speed Records in the "Altered Vintage" classes. I built the chassis as a platform to run these motors as both 45", 58", and 62.5" motor sizes. There were (4) new records set with my "Series Two" motors that are 62.5" at plus .100" overbore, and the long 4 7/16" stroke. Later, with these motors, I added my 45" flywheels, and 45" domed pistons to go for the "1,000cc Altered Vintage" class records using these parts. These cases, are replacement "741" cases, because the original cases are still in the bike, because they have been altered in the motor mounts. Otherwise, they are identical very good cases. I prefer the "741" cases, because they have the timing hole on the left case side (otherwise they are identical to Sport Scout cases).

When I set out to achieve a goal, I pull out all the stops. I wanted to go to Bonneville, and to put Indian back in the record books. I admire what Burt Munroe did, but I had a different goal. He used some parts from his 1920 Indian Scout, including cases, primary, and tranny, but the basic motor was a 920cc "Over-Head" valve motor of his own design, with 14:1 compression! I wanted to use the Indian factory Scout architecture to un-seat the prior records set by both Harley-Davidsons, and Triumphs. My bike uses true Indian Scout

"Flat-Head" motors. They performed very well for me, and put Indian back in the record books for (8) seperate classes. No other vehicle at Bonneville has set as many different class records! These are the fastest "Indian" motors in the world. So, who really does have the "World's Fastest Indian"? I think that I do (at least Indian powered). The top speed for the bike was 177 mph, and I know it would go 185 with my last rider, but why keep chasing records after the bike made it's statement. In 2018, it finished setting it's 8th of (8) class records, and in 2019, I "up'd" (2) of the slower records into the next tens digit level. It was time to "pull the plug". So, I retired the bike in good condition. It's back on the street now, looking, and running like new!

Although these are very powerful motors, they are also "streetable". They don't have a wild state of tune! They were built to make a lot of torque at every opportunity. In the Bonneville "Fuel" classes, I would use a small shot of "Nitrous-Oxide" for an extra hit in power. I designed an NOS injection system that was predictable, and reliable. Since there were no high performance valve train, or other speed parts available, I had to re-design all the internals. I worked with Truett and Osborn on a perfected 58" Stroker flywheel set. I worked with Carrillo for super light, and strong rods (now you can buy copies from Jerry Greer's). I worked with Venolia and Arias Pistons to develope special high compression "Domed" pistons. I did a lot of combustion chamber design to increase both compression and flow. These motors have 8.5:1 compression, which is considered high for a Flat-Head. I have high quality Titanium valves, retainers, and keepers to reduce valve train weight down to 60% of original. I designed 7-coil valve springs for more pressure, and no coil-bind. I did a 1 1/2 year study on cams and lifters, and I figured out how to design modern high performance parts. I made small batches of my Racing Lifters, and Racing Cam Lobes to suit my needs. I still sell my valve train parts to racers world-wide.

I ported the cylinders, and added special "Manganese Bronze" valve seats to assist valve cooling. I have always maintained a "5-Angle" racing valve job, and optimum valve stem clearance. I designed (4) performance cam grinds, and the best choice are in these motors. I increased the valve lift from .330" (Stock), up to .423" for more flow. My new Racing Lifters are made from "4140" chrome steel, and heat treated. I make special "Needle Bearing Rollers", for high lift, and high spring pressures. It took a lot of research, and testing, but I am very happy with the results. My cams and lifters are wearing better than the factory stuff!

I picked a Keihin "FCR41" carb for these motors to race in the big motor configuration, but these motors are equipped with the smaller Keihin "FCR37" carbs that I ran in the small 45" motor classes. For street, these are a better choice, and will offer excellent throttle response, and plenty of power. I use the original intake manifolds with a custom carb adapter, that I ported for performance. These will flow a lot better than any other choice! At first, I had Morris Magneto build me some very hot Magnetos, but they created too much rotational drag, and I had a hard time keeping them from twisting themselves out of the oil pumps. So, I switched over to original distributors with hot coils, and pointless ignition modules from then on. These motors have new "Joe Hunt" magnetos with a good reputation. I like to "Lock" the mags at 30 degrees BTDC (no advance/retard). I would do a stock front header with a long 1 5/8" tail-pipe all the way to the back of the rear tire for best performance (NO drag pipes!).

Here are some other mods that I like to do. I modified the cases to use the 1947 Chief oil sump "Scraper". I do a special lightening job to the flywheels to lighten them over-all, while maintaining outer mass for high RPM inertia. I rotate the push-rod guides to put the oil groove on the right (uphill) side, then precisely hone them for a .001" fit to new spiral grooved push-rods. I add a drive race seal, like the '52-'53 Chiefs. I use thin "Brown Paper Bag" cylinder base gaskets for good sealing, and a tiny bit more compression. I use Teflon valve guide seals for the intakes only. I have Cometic Gaskets make me .050" thick copper head gaskets custom for my modified combustion chambers. I gave up on factory head bolts a long time ago. I custom make stainless steel studs, and use the older Indian chamfered washers, and ARP Grade-10, 12 point "Flange Nuts" at just 50 Ft/Lb of torque. Much better head clamping (no blown head gaskets). I had these "Dick Holt" cylinders "Nikasiled" for a much harder surface. The original iron bores are soft, and wear quickly (they also score pistons when it gets hot!). I use a piston coating company that has the best coatings. They do a Ceramic top coating to cool the piston tops, and I use their Deisel skirt coating, which is very tough, and protective. Without their coatings, I would ruin a top end after every run! I also make special "Manganese-Bronze" thrust washers that go to the left of the Female Rod. I was experiancing severe wear of these original steel T-Washers at Bonneville, that threw off a lot of metal trash into the oil. It is a complicated story, but the new Manganese-Bronze" T-Washers don't wear like steel, and my problems were solved.

After every trip to Bonneville setting new records, I would do complete re-builds, with forensic studies. I would see weird wear, and parts failing, until I started modifying the clearance specs. After many years of racing, I found the best clearances to use for long life. I built these motors (and every other new Scout build) with these specs, because I trust these numbers. I have a seperate spec sheet for each of these Stroker motors for sale, and you can read them here below! Therefore, there is no mystery to these motors. These are "Blue-

Printed" motors, with the data provided! I have cost sheets for these motors, and you can see that they are identical for each motor. That's because they are identical in parts and work. Take some time to study the specs, and costs. These are very powerful, and streetable Scout Stroker motors like you will never see again. In 2016 at Bonneville, I did a "3-second" test with the "Nitrous-Oxide" system on my dyno (it's my racing trailer as well). With a small shot of NOS, it made 240 "Crank" horse-power, and 187 Ft/Lb of torque (in top gear). That is (8) times the power of a factory 45" Scout! Below, you can see a video of a starting line run at Bonneville for a new record. It went 164 mph with the small 45" motors (2-back to back 164's!).

Motor Spec Sheets

Parts List, Prices, and Total Costs

Picture Gallery below, during the Build

So, what do you think?

CONTACT INFORMATION:

James R. Mosher

(505) 466-7870