Indian Performance Pistons

You are looking at an Arias 58" Stroker Scout piston on the right with the longer skirt length. On the left is another option, with a modern slipper-skirt, which I have found does not work as well for long life. The long skirt will help prevent piston rocking.

Top ends have always been a problem with Indians. In fact, in 1940 the Indian factory even strengthened the cylinders by making all cylinders as "Square Base" cylinders. They must have been suffering severe seizing, resulting in cylinders breaking off at the cylinder base. I have seen this many times myself with older "Round Base" cylinders. The factory pistons were "die cast" low expansion pistons, where they recommended a .0035" clearance when new. They also recommended a very long gentle break-in period. Today, you can buy a variety of die cast pistons of varying quality (some of them are very bad!). Forged pistons for severe duty can be custom made, but they are expensive. I tell people to spend the extra money, and set the clearances appropriatly loose, so they won't score, and the pistons will give a long life. Forged pistons tend to cost about twice as much as cast, but they can be custom ordered for diameter, pop-up height, skirt length, etc. The only cast pistons worth using "Off the Shelf" are the Taiwan pistons sold by Starklite Cycle, which go by the name "JCC", or "Superior". These are very high quality, hard walled pistons that are very low expansion, light weight, and last a long time, while resisting scoring. If I build a Hot Rod Chief, they are my choice! I just had to re-do a top-end on my 1947 80" Chief due to a broken valve adjuster, and I found the pistons to be just breaking-in. I was amazed! They have been in there for over 10 years, and have at least 10,000 miles on them. I cleaned them up with steel wool, and re-installed them. I have used "Jade", "Egge", and "Robbins" pistons, and they have all failed in a short time, because they are soft as butter. I can tell how soft they are when I cut the skirts down when making an 80" motor. The Taiwan pistons shed very fine metal bits, telling me that their cast metal is, in deed, harder. I built a 45" Scout with some "Egge" pistons, and in 236 easy break-in miles, the skirts shredded, siezed, and broke the cylinder off at the base. I setup the motor at .0045" clearance, and it was ridden in the cold of winter. They were too soft, scored, siezed, failed, and subsequently cost the owner around $2,500.00 to solve the problem. It pays to buy the good stuff!

For a Hot Rod Chief, it's pretty simple. Just buy the Taiwan pistons from Starklite, and have the cylinders honed for a .005" clearance measured at the bottom of the skirt's thrust face. Do a fair break-in by just riding the bike in a normal manor. Try to resist hot rodding it for 500 miles. The factories slow break-in is a bad idea. Just ride the bike, where it is just free-wheeling along, and don't get it hot. Change the oil at 500 miles, and re-torque the heads at the same time to 50 ft/lbs. For an 80" motor, you hold the normal 74" pistons gently in a big lathe, and turn off the bottom .150", so they won't hit the flywheels. While still in the lathe, gently run a flat file along the bottom sharp edge to knock off the sharp edge. When installing rings (it doesn't matter who's rings), do not install the 3rd compression ring. Just leave it out! These pistons in a 74" will have a piston top just under the cylinder deck, but when shortened, and installed in a 80" motor, they will pop-up by around .150" just like the factory 80" pistons. I personally feel that these Taiwan pistons are good for all-out racing applications in a Chief, as long as you have adequate clearance. If you are going to really abuse a Chief, I'd set the wall clearance to .006", and they will work just fine. For 74" Chiefs, the Taiwan pistons are a great choice, but they do not make a 74" Bonneville "Pop-Up" piston. Some people offer them, but stay away! They are soft, and very heavy. There are other better ways of making power. Just use the Taiwan non pop up piston for better service! Anyway, I don't like building a 74" motor, when it's so easy to convert it over to an 80"er. I firmly do not believe in 84", or 88" motors, because the longer stroke is just too much. I have found in the field that my 80" motors easily can beat the bigger motors in a drag race. The 80" motor is the perfect size!

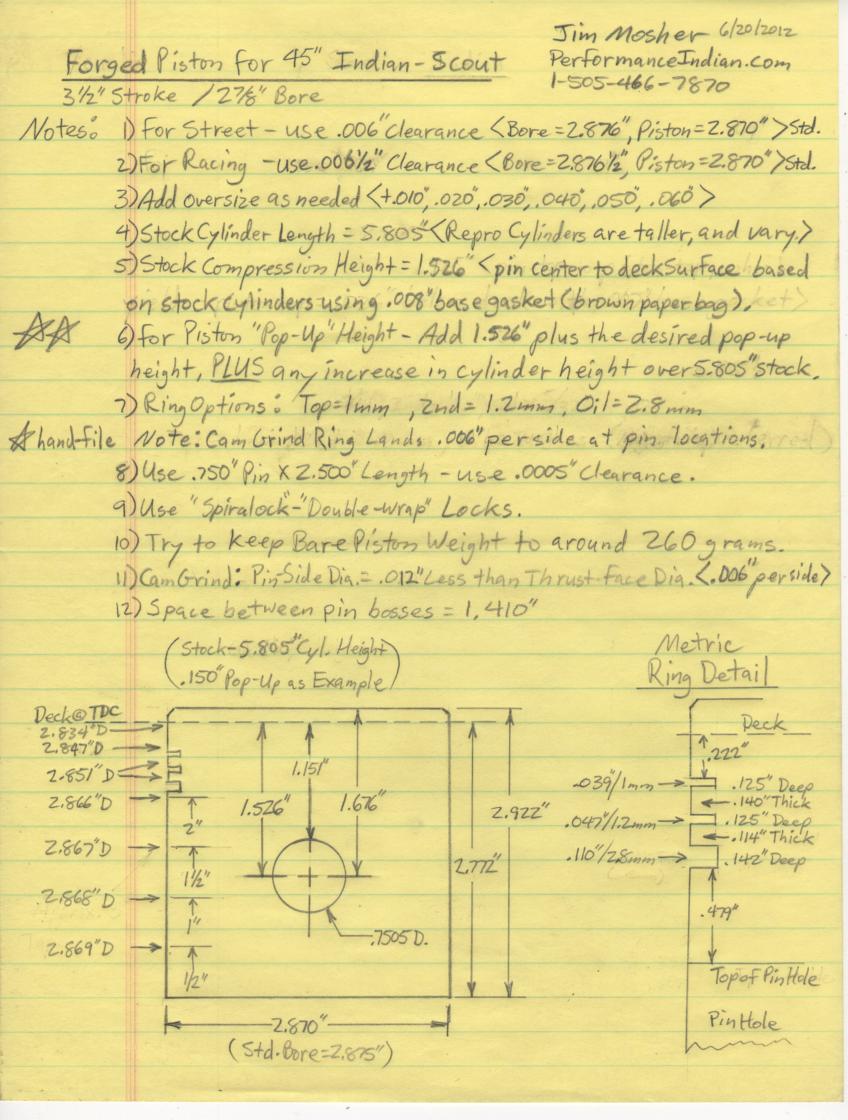

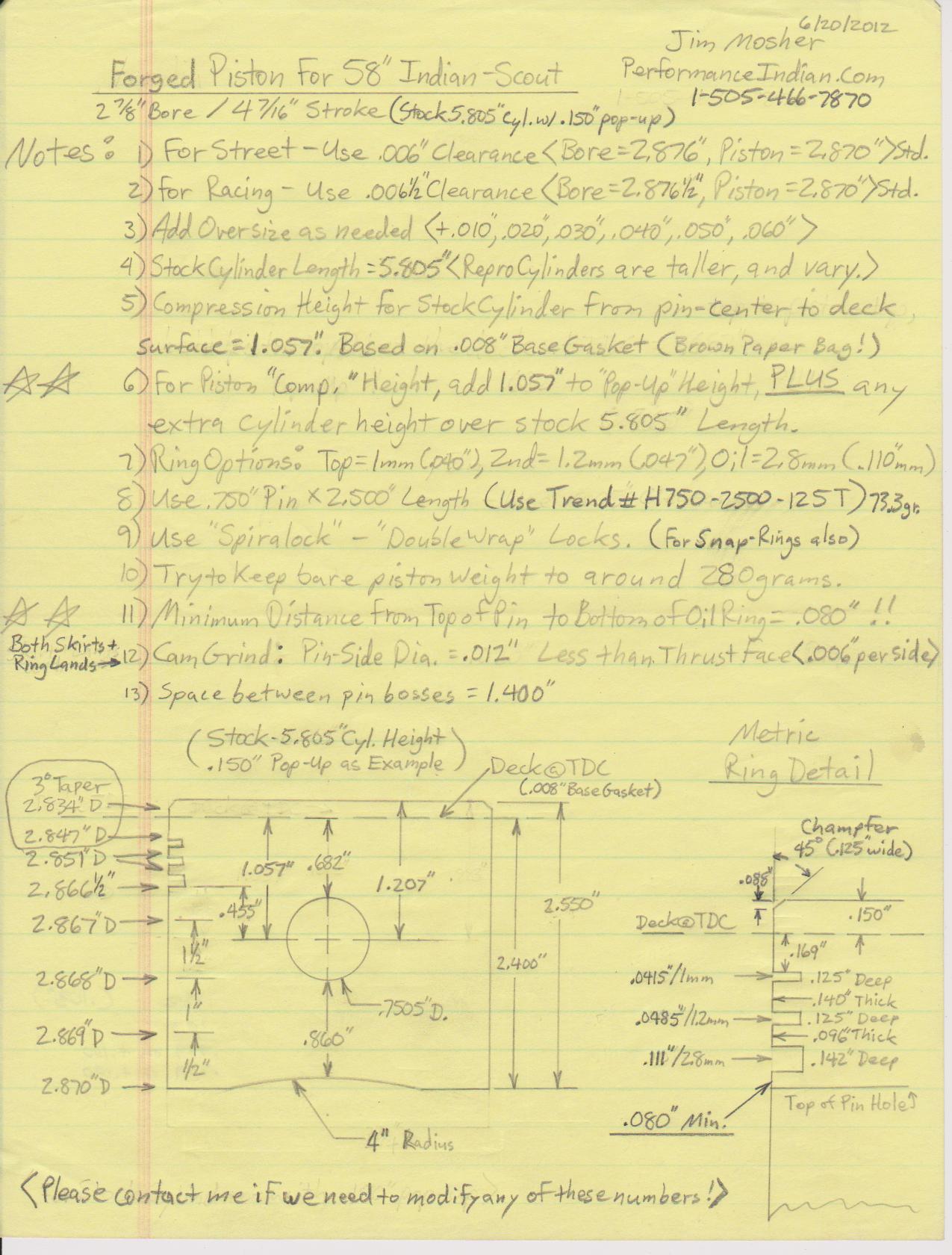

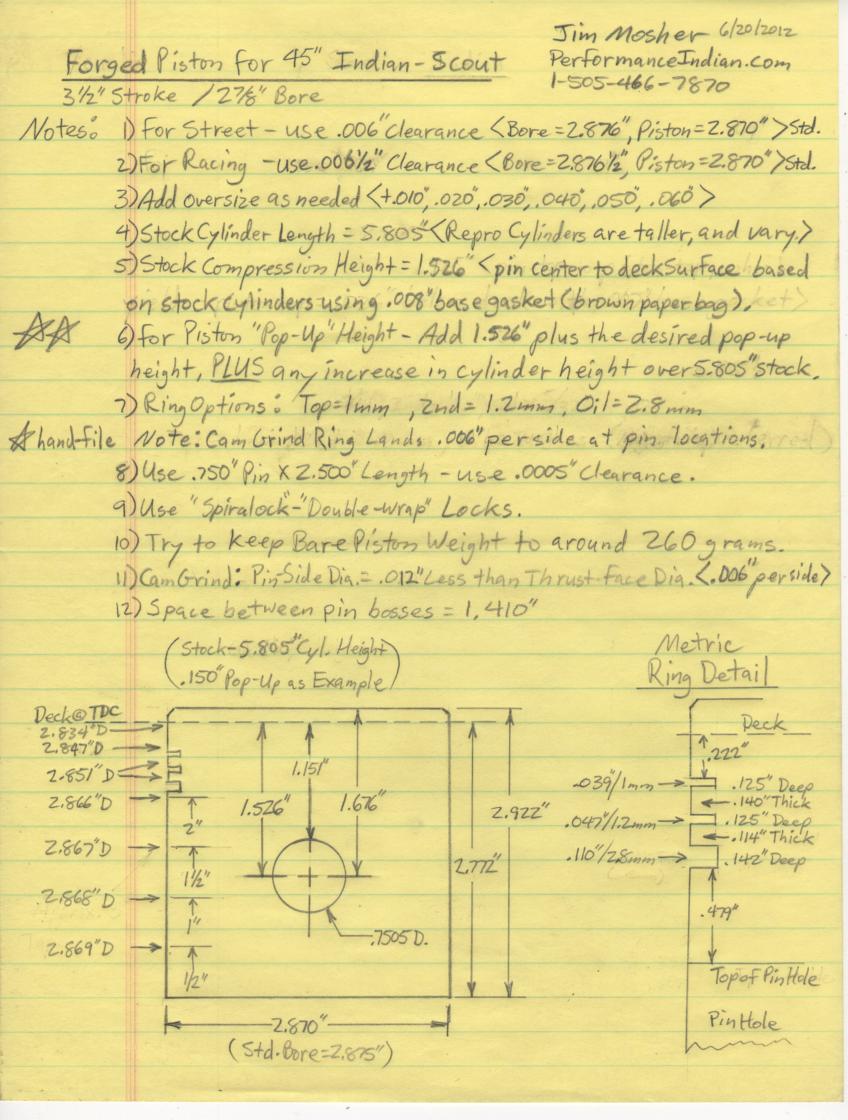

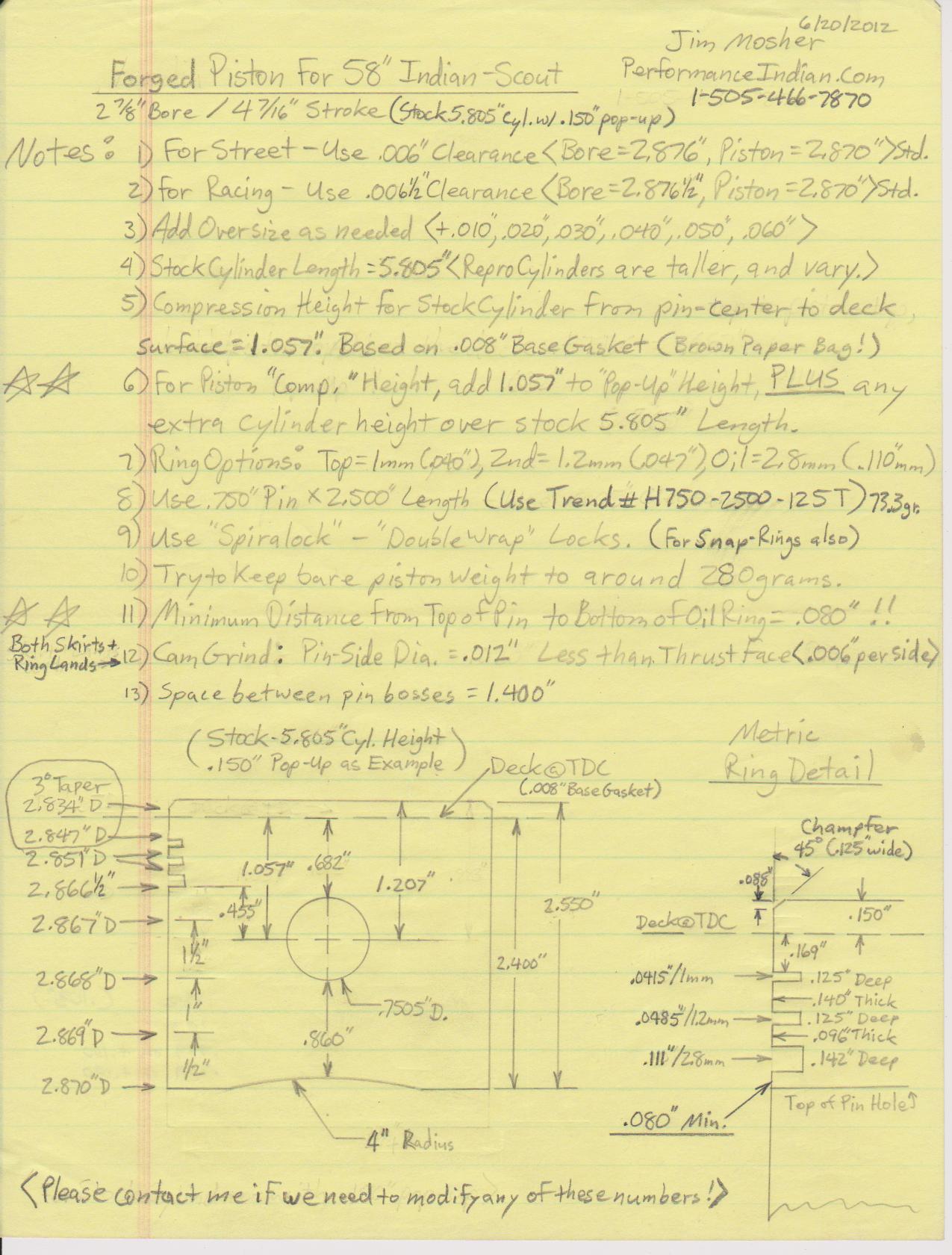

For Scouts, the choices are more limited. Scout Bonneville pistons don't exist, and almost all of the cast pistons are worse than junk. Don't buy any of them! Gary Stark is having the Taiwan factory make the same pistons as for the Chief, but again, they are short flat-top, with no pop up. If you want a pop-up, they need to be custom made in a forged piston, and this is where I come in. I have come up with a good design based on my many years experimenting with racing "Hot Rod" Scouts. I have suffered the many failures, so that you can benefit from the final design. I have used Venolia, Arias, and now Ross Pistons and found that Ross has a great product, and they are easy to work with. I have found that Scouts need a very long skirt to offset the tall (and heavy) height of the piston above the pin center. A short skirt piston will rock, and the ring lands will score the cylinders, leaving alot of nasty scratches in them, thus ruining the bores, rings, and pistons from debris shed from the pistons. Believe me, this is real! I am including here my drawings for referance. You can contact Ross Pistons directly, and ask for Chris Madsen (1-310-536-0100), and he can make you some superb pistons for around $400.00 per pair. You will have to carefuly read my drawing notes, so you can calculate the piston size, and stroke options.

To Order Ross Forged Pistons: Call (1-310-536-0100) Chris Madsen

The 58" pistons are for a "Stroked" Scout with a 4 7/16" stroke, while a stock 45" Scout uses a 3 1/2" stroke. At this time, Ross has only made me the 58" Stroker pistons. If you need pistons for a 45" Scout, you will need to lower the pin location by 1/2 of the 15/16" increase in stroke (15/32" = .469"). Plus, you will omit the (2) arched cuts at the skirt bottom below the pins (used for flywheel clearance for Strokers only). Mention this to Ross, but use the drawing for the 58" piston, because that is what they have on file. I have had (2) different batches made in "Standard" bore, as well as in "+.020" over-size. Each came with a "Job Card" number (148126 for 58" Standard Bore, and 147286 for 58" +.020" Bore). If you need a different bore size, use the Job Card for the "Standard" bore (148126), and make sure they know to increase the skirt and ring-land diameters appropriately. The NPR rings that they have supplied me in the past are as follows (Standard bore set = 21-GNH07300LT, and for +.020" = 21-GNH07350). Mention these ring part numbers to them!

Here are my (2) Scout piston drawings for ordering forged pistons. These specifications are perfected, and it is up to you to read, and understand the notes, so your piston order comes out right. If you make a mistake, your pistons will have that mistake!! Be diligent. Ross has these drawings, so basically, you need to give them the bore size, clearance required, and the pop-up (compression height).

Rings: Rings are a black science! I have used the worst rings with the best results, and the best rings with the worst results. Ross uses a Japanese ring from "NPR" that are affordable, and of superior quality. I have not been able to find them, and buy them directly. They come with the pistons, and can be re-ordered through Ross if needed. Total Seal also makes a fine ring, and they can make just about any ring you can conjour up. Their problem is that for the soft bores of the Indian, the 3-piece oil ring needs to be manipulated, so that they put less pressure on the cylinder walls. They are aware of this, understand it, and recommend that the end-user tune the fit to suit their needs. Their oil rings can make alot of drag, which will cause the oil ring to chatter as the oil ring goes up, and down. The inner ring of the oil ring needs to be gently squeezed at each rippled segment with some small long nose pliers, to reduce it's diameter. This is a job best left for a professional! It can be frustrating. The oil ring drag can be measured in the bore by first mounting only the oil ring to a dry piston, and installing it into a dry bore. The piston should have the pin installed, and by using a common "Fish Scale", you can start slowly pulling the piston upward in the bore, and after it breaks free, it should show a drag of between 10-12 pounds drag. I have seen as much as 25 pounds drag right out of the box, which will wreck your bores. I always check the oil ring drag on performance motors. After the beak-in period, this drag will be down around 7 pounds, which will seal oil, and not produce any wear. I have seen several bores ruined by not checking the oil ring drag! I have used many sets of Total Seal's "Gapless" rings , and I love them! On the other hand, I have used the cheap cast iron rings that come free with the Taiwan pistons for the cheapskates, and they also work well. Go Figure!

Ring End Gap: Ring end gap has always been spec'd out as .004" of gap per 1 inch of bore size. Therefore, a Scout would need .012" ring end gap for the (2) compression rings (end gap does not apply to oil rings). In the racing field, I have found this to be way too tight. I set my Twin-Scout rings at .015", and they, in deed, closed the gap, which causes the rings to create a tremendous drag on the bores resulting on severe scoring. My case was minor, and I was able to hone out the damage. I am now running .020" ring end gap on the Twin-Scout. For "hot Street", I like .018" ring end-gap. This applies to Chiefs as well. The ring end gap will, in deed, allow blow-by gases to pass through, but in racing, these gaps close down more, and become irrelivant! Tight rings do damage!!! For a slow street bike that never gets very hot, a tighter gap (around .015") will slow down the blow-by to keep the oil cleaner. Think about it!

Some things to consider that influence the life of pistons, and rings are heat, and oil consumption. Two things that are mentioned in other sections of my Tuning section cover Intake Valve Seals, and Keihin CV carb kits. I have done so many Indian motor rebuilds, and everyone of them gets a "Forensic Study". I want to know what works, and what doesn't. I have always noticed that there is alot of hard burnt oil crust built up in the combustion chamber, and cylinder deck near the intake valve. This is because Indian didn't use any form of valve seals. The flat-head motor unfortunately needs alot of valve guide clearance, which allows alot of oil to be sucked up into the combustion chamber at the same time that the crank case pressure is blowing oil up the intake valve guide as the pistons are going downward on the intake stroke. A double whammy! The intake valves need valve seals, while the exhaust valves don't. The exhaust valve always has a suction working in the opposite direction from the intake, so oil doesn't want to get into the exhaust guide. I did a test on my own Chief by installing intake seals 15 years ago, and the combustion chamber, and piston tops stayed clean with no oil deposits forming. In all of the motors that I have inspected with no seals, I have seen severe piston, and bore wear directly below the intake valve area. As soon as your skirts, and bores are wrecked, you can bet that your rings are shot as well. That's why most Indians have a severe compression leak-down problem. The bore environment is wrecked, and needs a rebuild! Most Indian riders are suffering this dilema, and feel that it is just normal. Intake valve seals can double, or triple the life of an Indian top end!

The other thing mentioned above is heat. Linkert carburetors are so primitive that they aren't even as good as a common lawn mower carb. They have an idle circuit that runs out shortly after the throttle is opened, and the high speed circuit comes in way too late. This causes a severe lean situation right where you want to ride the bike. There is no cross-over circuit! They will actually make fair power at wide open throttle, but what about the rest of the time? I am a carb expert, and have been since since I was 11 years old. I know how to modify, and solve all the Linkert problems, but I just don't see it as worth doing. It won't be easy, and practical for your average Indian (or Harley) rider. It is easier to replace the Linkert with a more modern carb if you intend to enjoy your bike. After much frustration, I experimented with carb choices on my Chief. I went to a Death Valley Road Run, where at least 40% of the riders lost their top ends due to the crappy (and expensive) California gas. My pipes got burnt, the motor was smoking from scored pistons, and I wasn't alone. After looking at all the options, I chose the Keihin CV 41mm carb found on millions of Harley-Davidsons. There are (2) jet kits available for them (Dyno Jet and Yost Power Tube). The Yost Power Tube is infinitely better than the Dyno Jet kit. Every CV installation kit I sell usually has a Yost kit sold with it. The factory H-D jetting is inappropriate for an Indian, and just doesn't work. The H-D factory jetting had to satisfy the 50 state EPA requirements for polution, so they were lean, which caused alot of H-D owners to remove them (I'm glad they did!). Keihin CV's used to be cheap, and easy to find, but since the H-D guys found out that they could be adapted to older H-D's with a Yost kit, they are becoming increasingly more scarce. They made so very many of them from 1988-2006, that they can easliy be found on E-Bay. Get one before they are gone! About $150.00 should get a very good one. Take a look at my Dyno Chart section, and you can see how good these CV's work. They make a ton of power, while making the motor run about 150 degrees F cooler, and gas milage goes from about 38 MPG to over 53 MPG! The reason for this discussion here is that the motor runs much cooler with a modern carb, and the cylinders remain round. With the excessive heat from a Linkert, the cylinders distort, and become egg-shaped. The rings just can't cope with this. That's why most Indians have such severe leak-down while kicking them. I hone alot of cylinder bores, and you wouldn't believe the distortion that is in the bores after they have run very hot. I have honed bores after running Keihin CV's from the beginning, and they run very true to the original hone job. Think about it!

For Scouts, the Keihin CV carb is just too big. Even a 58" Scout isn't big enough for the carb air velocity to be sufficient to get the diaphram-lifted slide to lift properly. I gave up after many hours of tuning. I thought about sourcing some smaller Honda Keihin CV carbs with jet kits for the smaller Scouts, but there would always be a limited supply. I feel that a Mikuni 36mm "VM Round Slide" is the best choice (especially for a 58" Scout). Their outlet bore is the same as a Scout intake manifold inlet. For a Bonneville racer I built, I bought one from Sudco. I raised the needle (1) notch, and increased the main jet (1) step from "out of the box", and the carb was perfect. It ran extremely well, and went 30 MPH faster than it did with it's Linkert for a new Land Speed Record! To re-cap: Keihin CV's with a Yost Power Tube for Chiefs, and a Mikuni 36mm VM Round Slide for Scouts.

CONTACT INFORMATION:

James R. Mosher

(505) 466-7870